These are tough times, with companies of all industries and sizes facing economic uncertainty. Despite staving off a recession, leaders continue to grapple with declining forecasts requiring them to reduce expenses and run more efficiently. Hiring freezes, labor shortages and postponed projects are common these days. All of this means most organizations need to figure out how to deliver more with less.

At ActivTrak, we use our workforce analytics platform to make data-driven decisions about workforce capacity planning. This “drink our own champagne” philosophy has fueled numerous innovations that help identify common workplace problems like burnout, constant digital distractions affecting focus, workload imbalance and more. In the examples below I’ll walk you through some of the ways we’ve leveraged them to meet – and exceed – our business goals.

What is workforce capacity planning?

Workforce capacity planning is a process businesses use to determine how much work can be done with current employees and inform future staffing decisions based on predicted needs.

Basic capacity planning focuses on employee hours in relation to the total workload. For example, a workforce of 15 employees who each work 40 hours per week has a total workload capacity of 600 hours to devote to projects.

However, this approach to workforce capacity planning doesn’t account for factors like individual employee productivity and capacity. For example, some employees may be more productive than others, allowing them to do more in the same amount of time. Additionally, differences in individual capacity can affect planning. An employee who’s integral to several processes may get into a situation where they’re being overutilized and working above their capacity, which could lead to burnout or bottlenecks in workflows.

Using additional data can help organizations conduct workforce capacity planning more effectively for more accurate insights.

With this in mind, we analyzed our internal productivity data to inform short-term workforce investment and efficiency strategies – exploring questions such as:

- Where can we not afford to rehire or backfill?

- How do we redistribute or absorb work among the existing workforce?

- Who can take on additional work and which teams need additional support to deliver results?

- Can I justify hiring “x number” of new employees for teams that directly impact company growth?

It’s important to note this analysis is about capacity and not performance. You can have a top performer with bandwidth to help others and you can have a poor performer who is over capacity.

How to conduct workforce capacity planning

Our planning software simplifies the workforce capacity planning process. Here’s how:

- Establish the expected capacity

- Analyze actual vs. expected capacity

- Identify opportunities and risks

1. Establish the expected capacity

The expected capacity (or Expected Total Productive Hours) for every team member is calculated based on two inputs:

- Productive Hours Per Day Goal (e.g. 6.5 hrs/day). This is usually set by the manager based on role and seniority. Learn more about ActivTrak Productivity Lab’s recommendations on how to set data-driven goals for your teams here.

- Expected Days Worked. This is the reasonable number of days employees are expected to work after accounting for holidays, vacation and sick days. For the full year, that was 260 weekdays minus 10 holidays, 20 vacation days and 8 sick days = 222 expected days worked. The “expected days worked” number is typically ~ 85% of the workdays in the time period.

Expected Total Productive Hours = Productive Hours Per Day Goal x Expected Days Worked

2. Analyze actual vs. expected capacity

We calculated the Total Productive Hours for each team member by multiplying the number of Days worked (Active Days) x the average productive hours per day. Then, we compared their Total Productive Hours to their Expected Total Productive Hours to determine their FTE or Full-Time Equivalent Capacity %.

User Capacity = (Total Productive Hours / Expected Total Productive Hours) * 100

3. Identify opportunities and risks

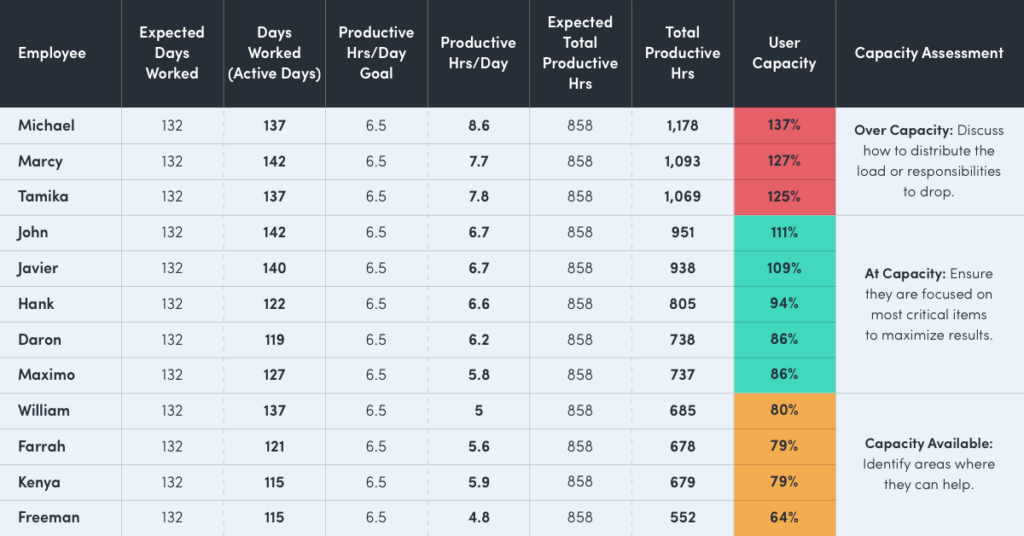

Using the metrics described above, we identified the following scenarios:

- At Capacity: If team members’ User Capacity was between 80% to 120%, we considered them to be “at capacity” and recommended they remain focused on the most critical tasks to maximize results.

- Over Capacity: If team members worked more than 120% of their Capacity, managers should support them by taking work off their plates and distributing it to team members who are under capacity or at less than 80% of Capacity.

- Capacity Available: If team members’ Capacity was less than 80%, they were deemed good candidates to take on work from over-capacity team members or any employees who have departed the organization/team.

A data-driven workforce capacity planning process

Here is an anonymized example using the approach described above, leveraging the productivity data from Q3 and Q4 2023 for one of our ActivTrak teams.

The insights above allowed the manager to collaborate with their team members to make the following adjustments:

- Freeman absorbed part of the responsibilities from another team’s employee that left the company in Q3.

- Kenya took over the coordination of a couple of customer programs from Employee 1 to help reduce her burnout risk due to being overworked.

- Farrah will now be responsible for providing weekly reports on customer adoption that we were considering hiring a part-time contractor to do.

- William will work together with Employee 2 on a couple of upcoming projects to ensure the load is balanced between both of them.

In summary, this team was able to avoid two incremental hires (one permanent and one part-time), which resulted in annual savings of $250K and also significantly reduced the burnout risk of two high-performing team members. We saw similar results with other teams, so we have now incorporated this quarterly workforce capacity planning analysis as part of our operating cadence.

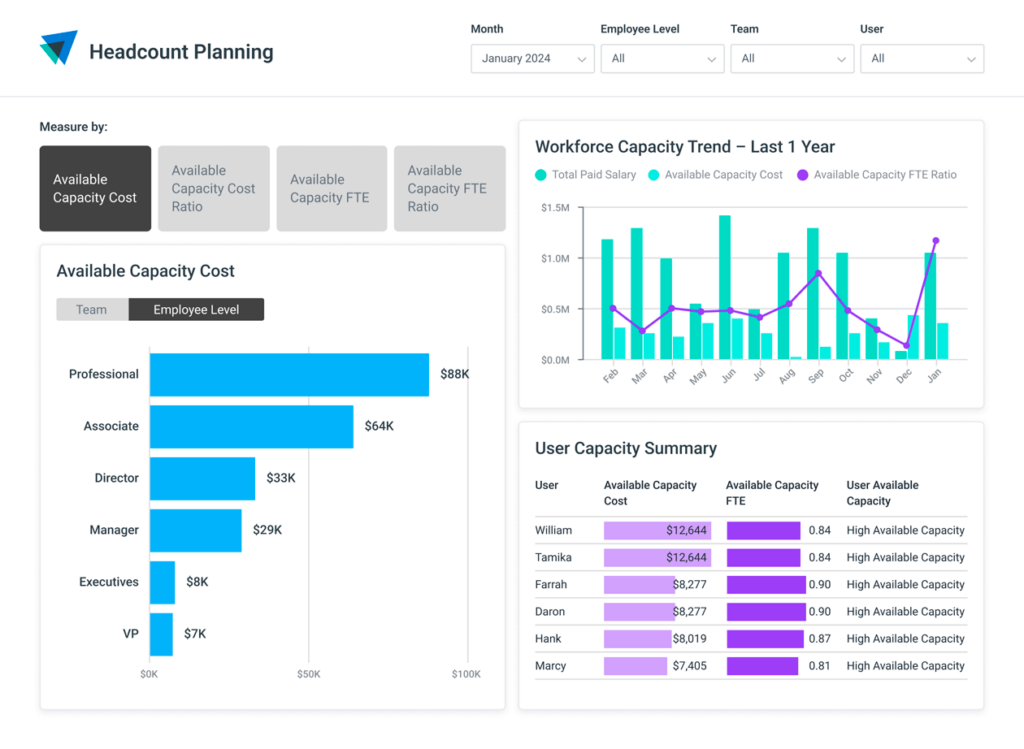

Workforce capacity planning: now available in ActivTrak!

Although the data we used in this analysis has been available in the Workload Balance, Location Insights and Workforce Capacity Planning Dashboards, the analysis was not optimized for headcount planning. That’s why we’ve introduced Headcount and Capacity Planning — a new custom dashboard that provides visibility into workforce utilization gaps to improve workforce planning. With Headcount and Capacity Planning you’ll be able to:

- Maximize workforce investments by identifying untapped labor capacity

- Identify overextended teams and detect quiet quitters to improve labor costs

- Assess utilization to drive data-informed efficiency strategies and staffing decisions

- Use salary data to quantify costs

- Set and track utilization goals to rightsize teams and balance workloads

Learn more about ActivTrak’s Headcount and Workforce Capacity Planning software or request a demo with one of our experts to see it in action.